Project Type: New Building

Implementation: Engine Cooling

Construction Year: 2020

Country: Germany

City: Rhadereistedt

Number of units: 2

Total air volume: 128.000 m³

Biggest single air volume: 44.600 m³

Smallest single air volume: 19.400 m³

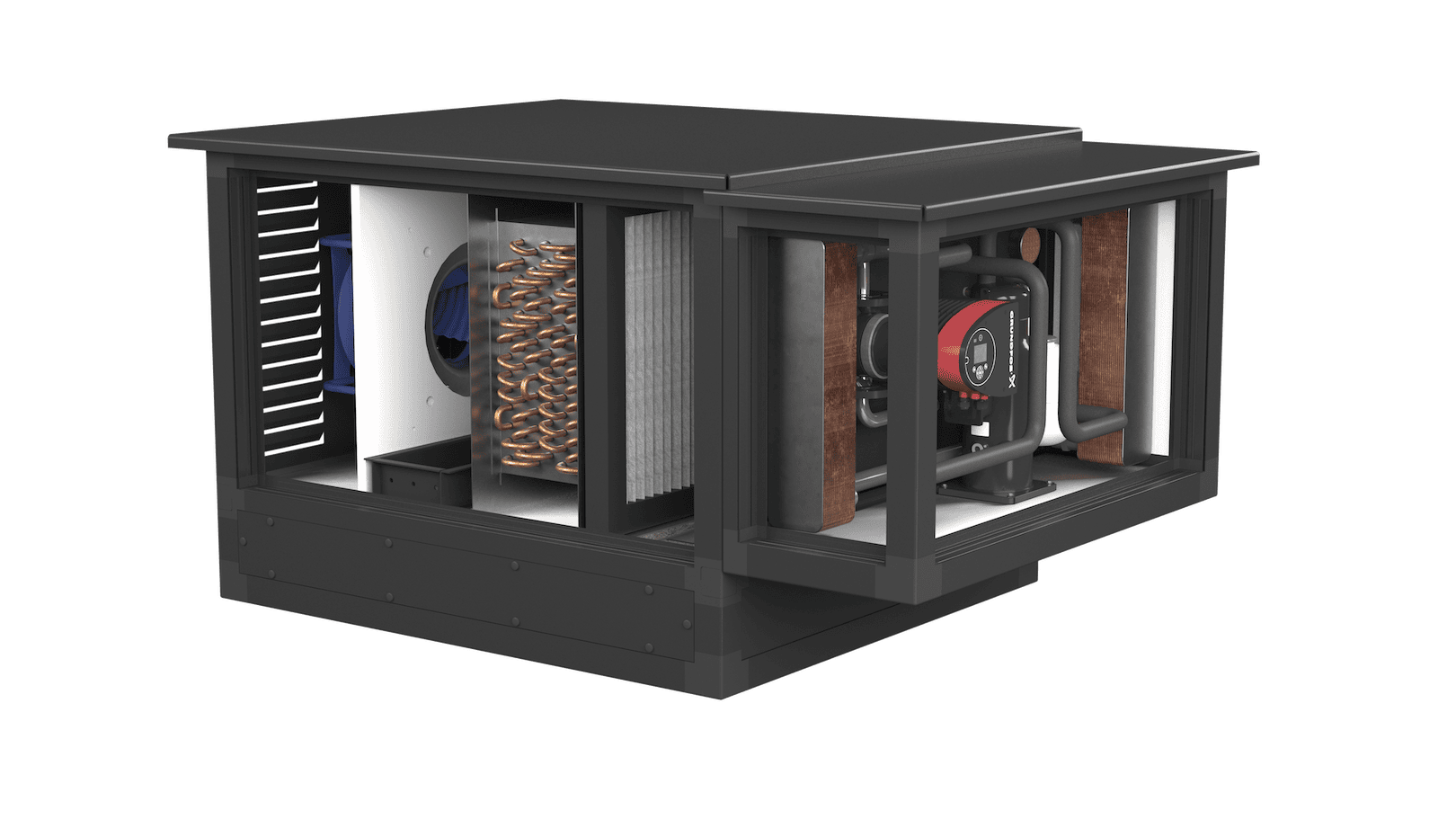

Series/ Line: SKW6.4 + 8.4 & SKW7.7 + 8.7

Outdoor installation: 2 of 2

Flatpack: no

Special features: 2 outside units

Controls: yes

Swimming Pool with SPA and Sauna Center in Tõrva, EstoniaNext

Swimming Pool with SPA and Sauna Center in Tõrva, EstoniaNext Chateau d’Urspelt ventilation renovation, Luxembourg

Chateau d’Urspelt ventilation renovation, Luxembourg

Advanced Biogas Plant Engine Cooling Project in Rhadereistedt, Germany

Project description

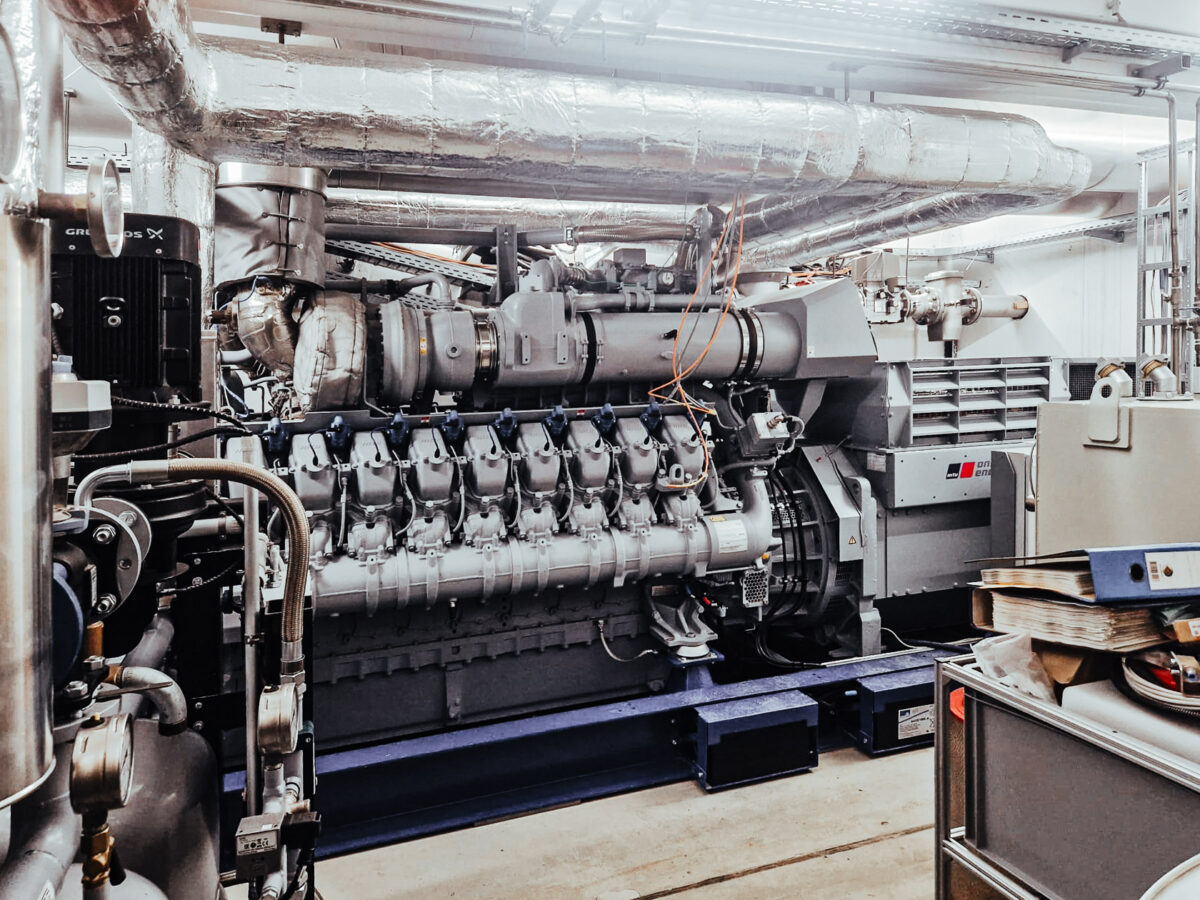

The goal of the project was to dissipate and utilize the waste heat for two CHP engines in a biogas plant. The engines were located in a specially separated building on the site of a biogas plant, with one supply and exhaust air unit for each engine.

There are two main ways in which heat is dissipated through the engines. First is heating through the internal cooling system. The second is radiative heat through the body of the engine. Each of these presented a unique challenge.

Exhaust Heat Solution: When an engine starts up, the unit delivers the amount of combustion air needed. If the temperature in the room rises up, the unit starts to cool with fresh air. The same amount of fresh air will be added to the supply air. This process was controlled by sensors, ensuring consistent pressure for the engines.

Radiation Heat Solution: Air was extracted from the room, and the fresh air circulated. The challenge was to keep the pressure in the room the same as the ambient air pressure to make sure that the superchargers worked as efficiently as possible.

These challenges required a creative approach. We developed a special controls concept that functioned exceptionally well in this case.

In addition, the units were integrated into the fire protection concept by mapping various fire and explosion protection measures.

We are happy to say that the unit is functioning optimally, and the customer feedback was overwhelmingly positive.